Property

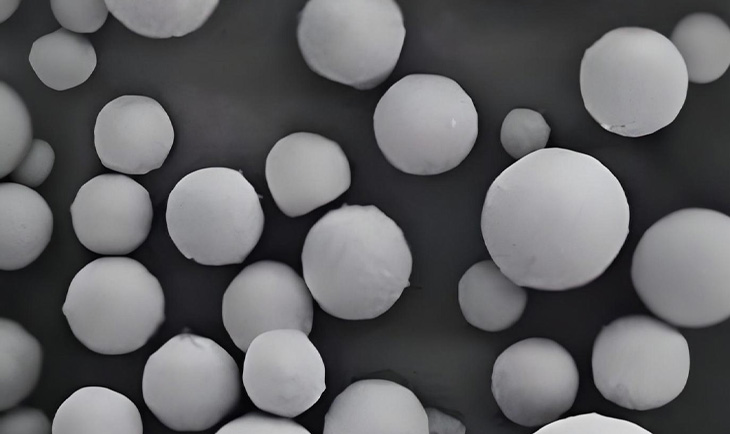

Alumina Ceramic Granulation Power is the higher application of Chemical Alumina and more development in Ceramic area.

The raw material of Calcined Alumina is the key of Alumina Ceramic Granulation Power

Application

It is suitable for automatic dry pressing and isostatic pressing process.

It is an ideal raw material for producing electronic ceramics and structural ceramic components.

Main features

- Loose packing with large density, quasi-spherical particles and good fluidity;

- Easy to form, no mucous membrane, high strength, small shrinkage;

- Porcelain forming temperature is low, sintering range is large and consistency is stable

- Porcelain has high density, high hardness and good ceramic performance.

Specification

| Specification | Unit | Type A | Type B | Type C | Type D |

| Al₂O₃ | % | 95 | 96 | 99 | 99.5 |

| Na₂O | % | 0.1 | 0.12 | 0.1 | 0.1 |

| Fe₂O₃ | % | 0.03 | 0.025 | 0.02 | 0.02 |

| D50 | um | 2.4-2.8 | 2.8 | 1.3 | 1.3 |

| Bulk Density | g/cm³ | 1.10-1.15 | 1.12 | 1.05 | 1.05 |

| Compaction Density | g/cm³ | 2.3-2.4 | 2.35 | 2.2 | 2.15 |

| Porcelain Density | g/cm³ | 3.7 | 3.8 | 3.88 | 3.9 |

| Shrinkage | % | 14-16 | 15-15.5 | 17.5-18 | 18.5-19.0 |